Time to improve

conveyor uptime

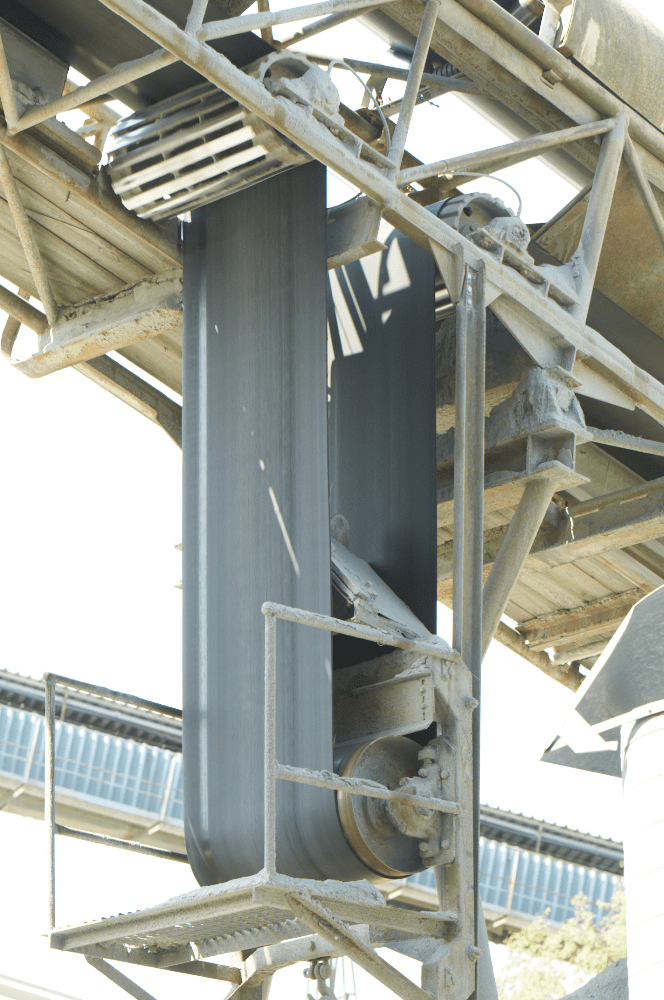

Availability is a constant challenge in mining. Change to a contamination-reducing bearing solution for pulley bearings and see your uptime rise.

The availability challenge

Stability is key in the mining industry. However, average conveyor availability varies between 84-88%, while four out of ten plants run below 80%. Only a few of the very best run above 92%.

At an SKF lifecycle management conference in 2018, a poll showed that conveyors are the most problematic asset in mining. We also know from case studies that pulley bearings are the main reason for conveyor breakdowns. So if you want to improve plant availability, a good way to start is by replacing conventional open bearings with a sealed alternative.

Why open bearings fail early

Open pulley bearings are relatively cheap to buy, and relatively easy to re-grease and replace. However, open bearings are exposed to dirt and high-pressure washdowns, while contamination and insufficient lubrication cause the bearings to fail early. Harsh conditions will always remain, but you can protect from them with a sealed bearing solution.

More working hours for conveyors

One example of a contamination-reducing bearing solution is the SKF Three-barrier solution. The pulley bearing is protected from ingress of dirt and loss of grease by three barriers. Whereas open bearings need regreasing every week, with the Three-barrier solution these intervals extend to several months. Extending Mean Time Between failures (MTBF) also makes it possible to take predictive maintenance to another level.

The SKF Three-barrier solution is specifically developed for mining. Read our insight paper and reference story, see your savings potential and feel free to contact us for a meeting.

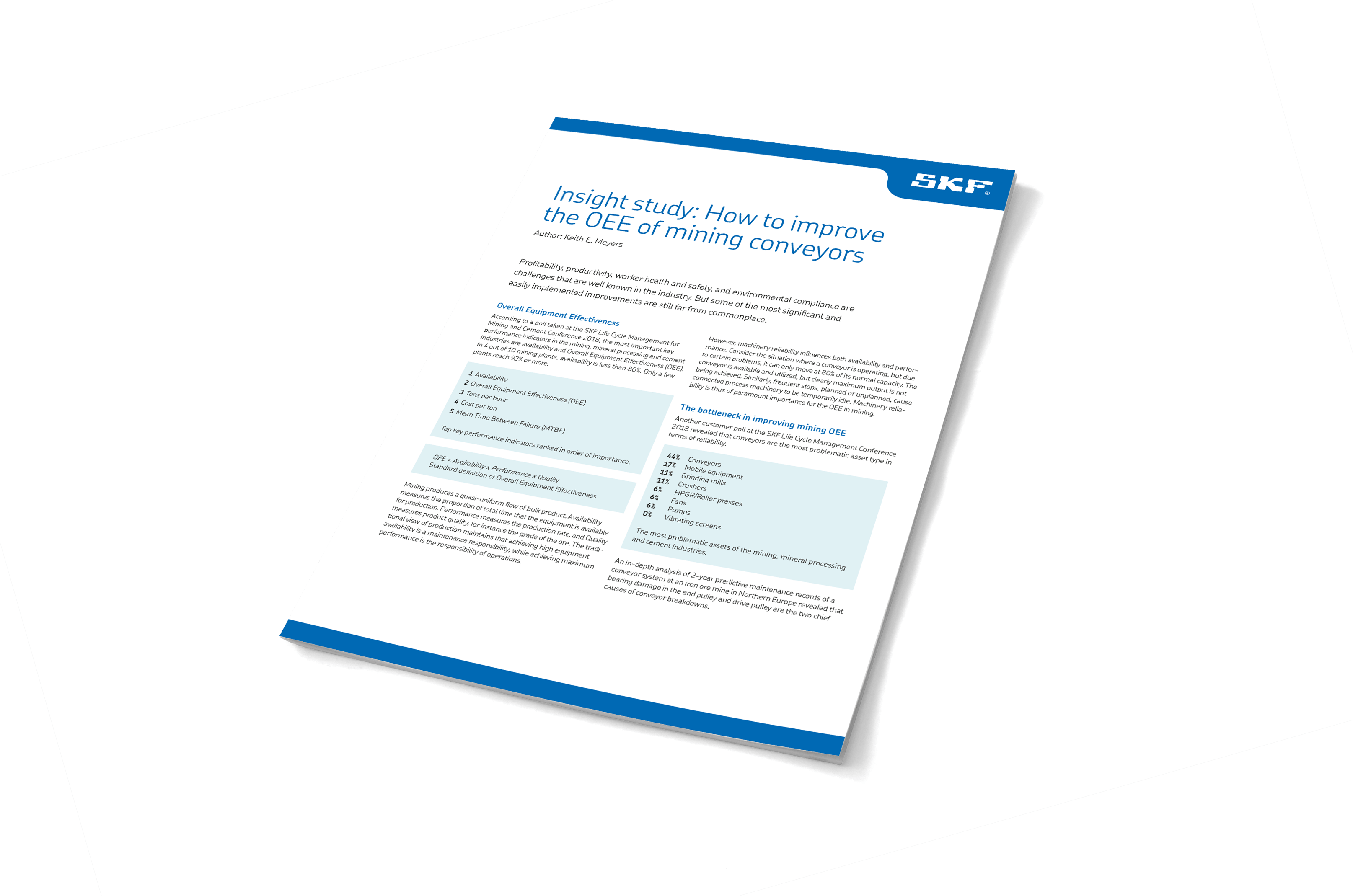

Easier than you thought: improving mining conveyor OEE

Overall Equipment Effectiveness (OEE) and availability are the most important KPIs in the mining industry, but many simple processes that can improve them still aren't widely implemented. Explore our insight study and discover the steps you can take.

Bearing protection in action

Bearing service life doubled and relubrication intervals extended by eight times. The SKF Three-barrier solution is making a real difference to this iron ore mine in Australia.

Start your journey towards 92% best in class conveyor availability

Conveyor pulley bearings in mining plants all over the world live a tough life, facing lots of dirt, heavy loads and high-pressure washdowns. The SKF Three-barrier solution protects pulley bearings from contamination and loss of grease.