The solution that improves conveyor uptime

Of all mining conveyor parts, pulley bearings have the highest failure rate. Replacing open bearings with the SKF Three-barrier solution improves conveyor uptime and can save millions of dollars.

Why conveyors break down

In a recent case study of a European iron ore mine, we found that damage to bend, drive and end pulley bearings was the main reason for conveyor breakdowns. The bearings were of the traditional open type, exposed to dirt and high-pressure washdowns.

Sealed bearings, on the other hand, keep the dirt out and grease in. The average lifecycle is three times longer than for open bearings, meaning less downtime: an important factor when one hour of operations in an iron ore mine can be worth as much as 100,000 US dollars.

Time for a new approach

Conventional open pulley bearings cause frequent mining conveyor breakdowns, despite intense re-greasing and replacement routines. A sealed bearing needs less re-greasing (as little as 10% of the grease of the open bearing) and has three times longer service life. Improving uptime by changing to a sealed bearing is attractive to any mining operator who wants to stay competitive.

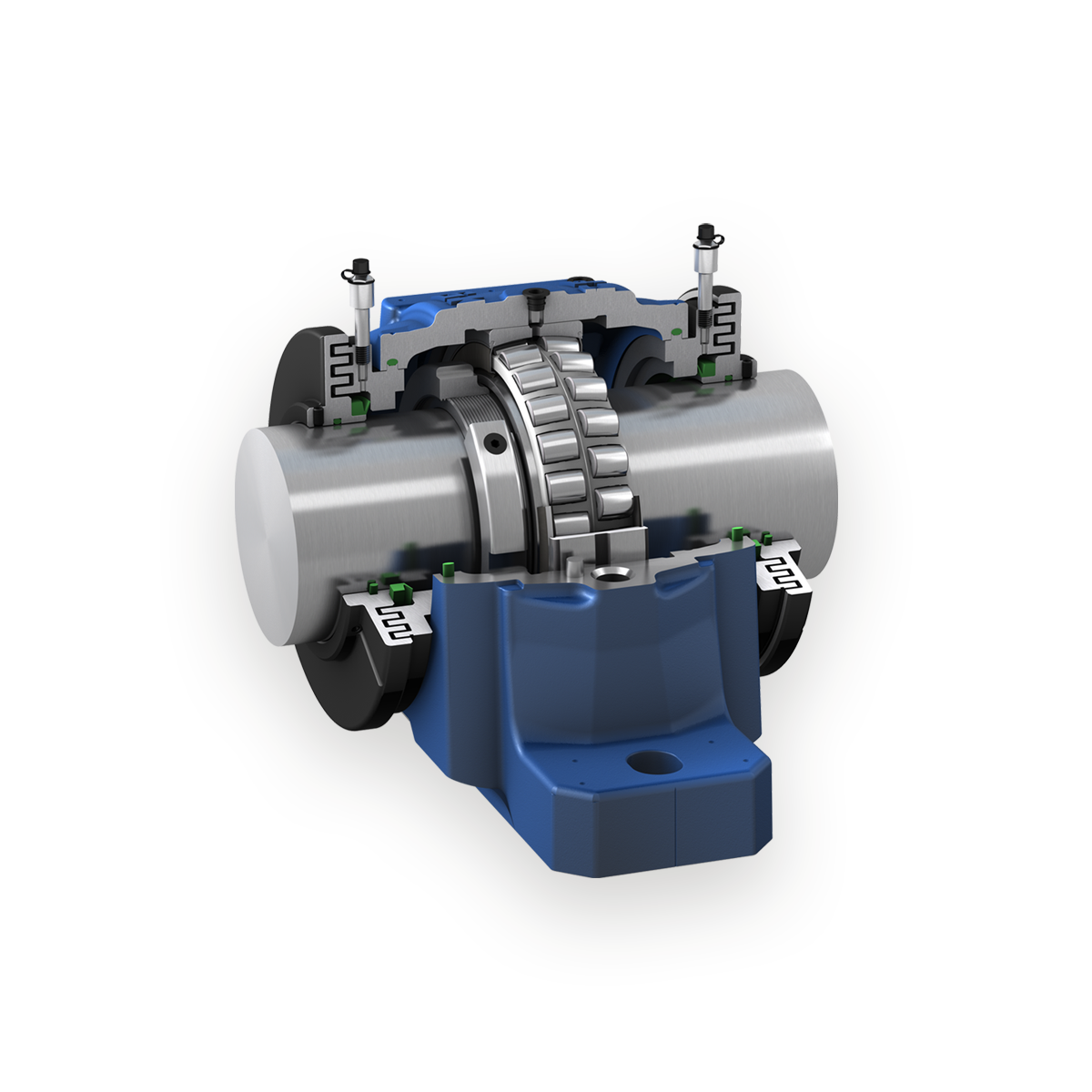

Three levels of protection

Since 2007, we have offered the SKF Three-barrier solution for conveyor pulley applications. The solution protects the pulley bearing from contamination and insufficient lubrication, the two main reasons why bearings fail early. Start your journey towards higher conveyor uptime. Talk to one of our expert team today and find out what changing to an upgraded solution may be worth to your operations.

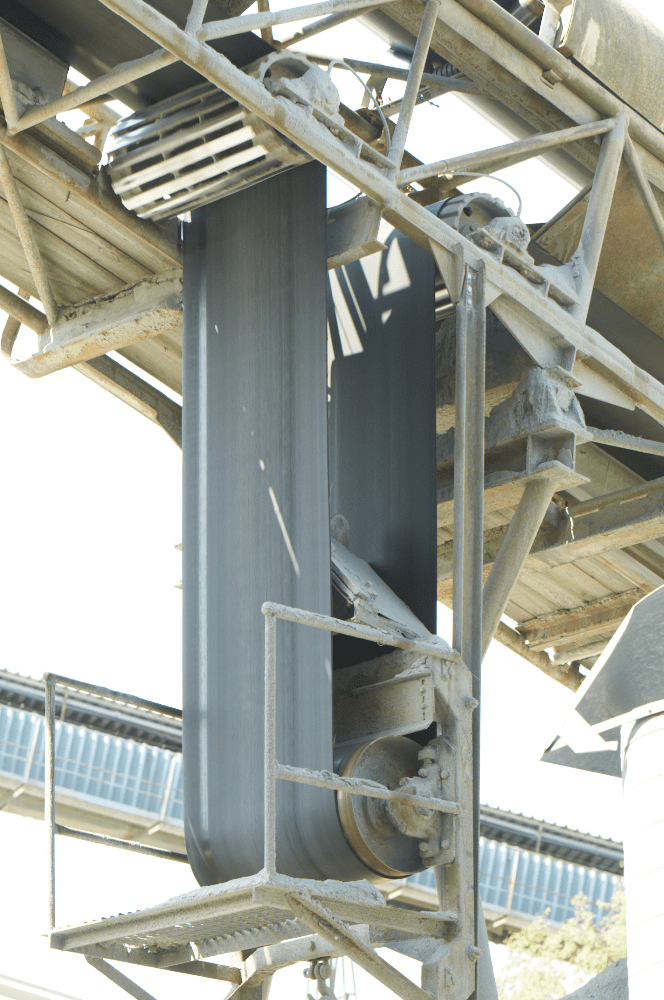

Bearing protection in action

Bearing service life doubled and relubrication intervals extended by eight times. The SKF Three-barrier solution is making a real difference to this iron ore mine in Australia.

Start your journey towards 92% best in class conveyor availability

Conveyor pulley bearings in mining plants all over the world live a tough life, facing lots of dirt, heavy loads and high-pressure washdowns. The SKF Three-barrier solution protects pulley bearings from contamination and loss of grease.